In the absence of formal standards, Ethan Biery of Lutron offers some guidance in the July issue for dealing with flicker. An excerpt follows:

Temporal Light Artifacts (TLA) are undesirable changes in visible perception caused by light modulation. Depending on the situation and the person in the lighted space, these changes can be very disturbing to occupants. Some types of TLA are visually apparent in a static environment–this is known as flicker. Other types, such as phantom arrays and stroboscopic effects, are only visible if the observer or an object in the space is moving. TLA is especially difficult to quantify because its perception can vary widely depending on the observer and the application.

TLAs aren’t necessarily bad. In nature, they can be beautiful– think about reflections off a body of water. But in the case of general lighting, there are significant negative effects associated with TLA ranging from mild eyestrain to catastrophic photosensitive epilepsy. Other potential concerns include headaches, visual or cognitive distraction and impairment, and interference with optical equipment such as cameras and computer vision systems (e.g., barcode readers).

All light sources inherently provide stable light output, but some light sources are more prone to TLA than others. What causes TLA is the stability of the power signal delivered to the light source, combined with how tolerant the light source is of any fluctuations in power. For example, high frequency electronic ballasts virtually eliminated the TLA problem that was once commonly experienced as a result of using low-frequency magnetic ballasts on fluorescent lamps.

Like other sources, LEDs themselves produce light output that is inherently very stable. However, LEDs are more susceptible to TLA because any fluctuation in the power source to the LED will become an instantaneous fluctuation in the light output—in other words, TLA! Incandescent lamps are particularly tolerant of fluctuations in their power quality because their hot filament filters out many fluctuations.

LED drivers regulate current to the LED. Simple, less robust drivers have a harder time preventing any fluctuations in their delivered power, and are therefore more prone to causing TLA. In addition, voltage changes to the input of the driver (e.g., power line or control noise) can also cause undesired fluctuation in the output. Finally, some drivers, such as those that use Pulse Width Modulation (PWM), inherently cause TLA, but in practice the frequencies used are beyond the detectable range of space occupants. The exception is drivers that output lower frequency PWM (500Hz or less); these may be prone to detectable stroboscopic or phantom array effects.

HOW MUCH FLICKER IS ACCEPTABLE?

Understandably, lighting designers are looking for an industry standard that definitively identifies acceptable levels of flicker and stroboscopic effect and can be applied in a wide variety of applications, but it’s best to proceed with considerable caution. Right now, existing industry metrics for measuring and mitigating TLA remain limited and somewhat controversial.

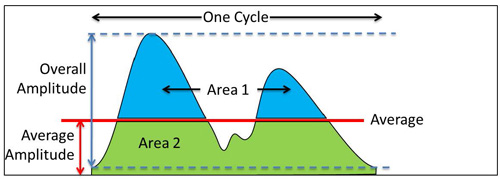

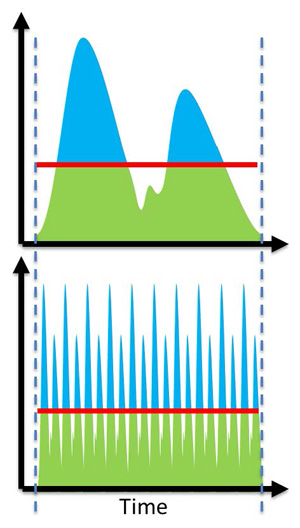

Until researchers can find a way to measure and replicate results that are consistent with human perception, while also controlling for all contributing factors, many lighting manufacturers and industry organizations are hesitant to recommend a particular standard or guideline. Two commonly cited TLA metrics are Percent Flicker (also called Percent Modulation) (Figure 1) and Flicker Index (Figure 2). These are easy to calculate and understand, but because neither method takes frequency into account, these methods may not have any correlation to actual human observation. For example, light waveforms fluctuating at 10Hz and 100Hz, that are otherwise identical in shape, will have the same flicker index and percent flicker, but will appear completely different to an observer (Figure 3).

![Figure 1: Percent flicker (PF) measured as PF = 100% X [(A-B)/(A+B)].](https://www.ies.org/wp-content/uploads/2024/03/Figure-1_PercentFlicker.jpg)

Flicker is a scientific measurement and needs to be treated as such in developing design standards and identifying appropriate metrics. Both NEMA and the Department of Energy (DOE) are actively working to characterize TLA and measurement devices in hopes of developing metrics that are reproducible and account for the wide number of variables in general-purpose lighting applications. The DOE has recently tested existing flicker meters against a benchmark to provide specifiers and their customers with better guidelines and recommendations regarding measuring and accounting for basic flicker parameters in their projects (https://energy.gov/).

One of the most immediate DOE goals, with regard to TLA, is to accelerate the development of standard test and measurement procedures to ensure that we develop metrics that won’t result in either widespread over-reaction or under-reaction, neither of which are in the customer’s best interest. NEMA is contributing to this effort through active development of an objective and reproducible method of measurement for general-purpose LED lighting.

HOW CAN YOU REDUCE TLA?

There are several things lighting designers and specifiers can do to most effectively use energy-saving LED solutions without giving up the quality of light that your clients expect and require:

- First ad foremost, keep in mind that the LED driver plays a very significant role in delivering flicker-free, high-quality dimming performance, and simpler drivers are more prone to flicker. Less expensive drivers generally have fewer filtering components and use analog instead of digital circuitry, making them more prone to external electrical noise sources, which can manifest as flicker.

- Use trusted manufacturers for fixtures, drivers, and controls and stick to what has worked for you and your customers in the past.

- Work with manufacturers who guarantee compatibility and performance between system components, such as drivers and control systems.

- Use digital control rather than analog whenever possible. Digital controls are less prone to noise and therefore less likely to result in interference-induced TLA.

- Consider doing project mockups for larger jobs. This allows experiencing and evaluating a proposed lighting and control solution in real time and in the actual environment. Mockups reduce the risk of finding performance problems on an installed job, when remediation becomes extremely difficult and expensive.

- Work with a quality manufacturer who demonstrates a commitment to testing thousands of driver, fixture, bulb and control combinations, and who makes those results public and easy to access.

TLA should certainly be taken seriously, as it can be a source of occupant discomfort and dissatisfaction, but until standards can be developed that account for all the variables in a lighting scenario, merely citing existing flicker metrics is probably not sufficient. Instead, work with high-quality, experienced manufacturers that will recommend, install and stand behind the right LED solution for your project. In the meantime, continue to follow IES, CIE and NEMA developments in flicker research, and join all of us in looking forward to a robust, reproducible and accurate standard for measuring TLA.