The results of a recent survey of manufacturers can help designers make healthier decisions about the products they specify

By Melissa Mattes

The architectural industry has made significant strides in the last five to 10 years in its sustainable offerings of products, building practices, cleaner materials and regenerative ideals. But where does this leave the lighting industry? By comparison, we are behind the rapidly expanding sustainable advancements of the larger built environment. While we are all familiar with discussing targets related to energy efficiency, we rarely have a larger discussion of holistic project goals, encompassing topics like materiality ideals across the entire architectural, engineering and consultant team. “Material transparency” is a key part of the conversation when making informed decisions about the products we specify, and their impact on greenhouse gas (GHG) emissions, health and well-being.

Doing business in an industry that is responsible for nearly 40% of all global GHG emissions, we have inherited part of the responsibility required to turn our environmental trajectory around. At Sladen Feinstein Integrated Lighting (SFIL), a Boston-based lighting design firm, we believe in the inherent civic duty and social responsibility that comes with the power of specification and design. To avoid passing along much larger problems to future generations, we have taken small steps within our realm of influence.

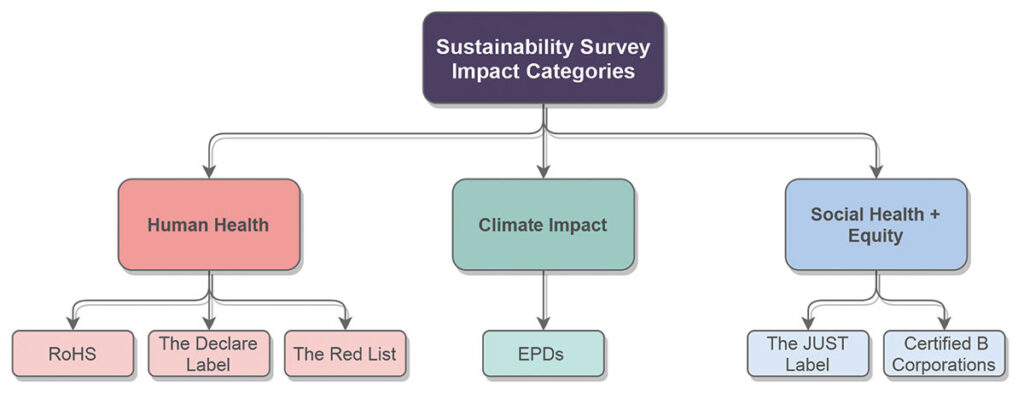

In the fall of 2020, my team and I launched an industry-wide sustainability letter and survey (see Figure 1 for the categories) with a two-fold purpose:

1. To express our desire for greater insight into the human health, climate impact, and social health and equity impacts of the products we specify and

2. To gauge manufacturers’ current familiarity with the labels and certifications available which quantify this data, as well as a five-year lookahead on product development prioritizing material disclosure to provide insight into human health and climate impacts.

This initiative was the first industry-wide research completed in the U.S. and was circulated to 167 manufacturers with results submitted by 65%, making the data statistically significant. This groundbreaking research became a launching point for a series of new conversations on the topic of sustainable lighting and material transparency and is at the forefront of trends evolving across disciplines in the AEC industry.

The survey had a few key takeaways that reflected the overall trend of increased popularity around material transparency platforms across the lighting industry. Where familiarity with specific labels or certifications was lacking, there was a strong willingness to learn.

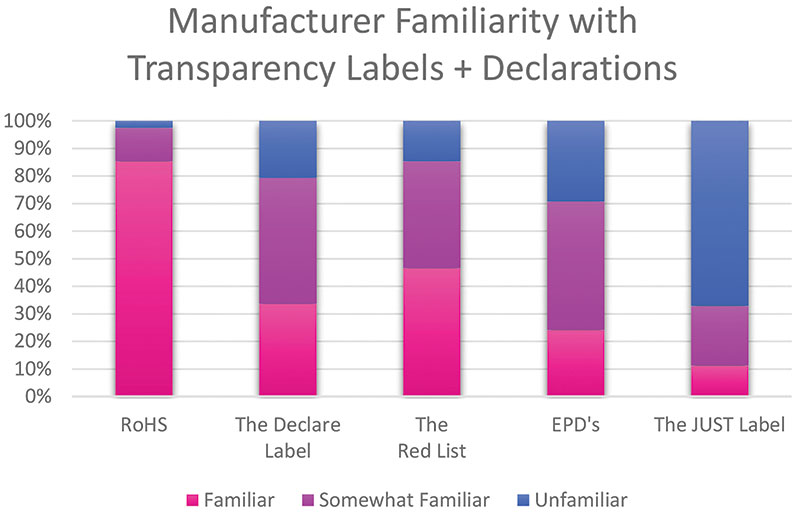

Human Health: Regarding human health, manufacturers were questioned on Restriction of Hazardous Substances (RoHS), the Declare Label and the Red List. We found that at least 80% of manufacturers were familiar, or somewhat familiar with all three initiatives (Figure 2).

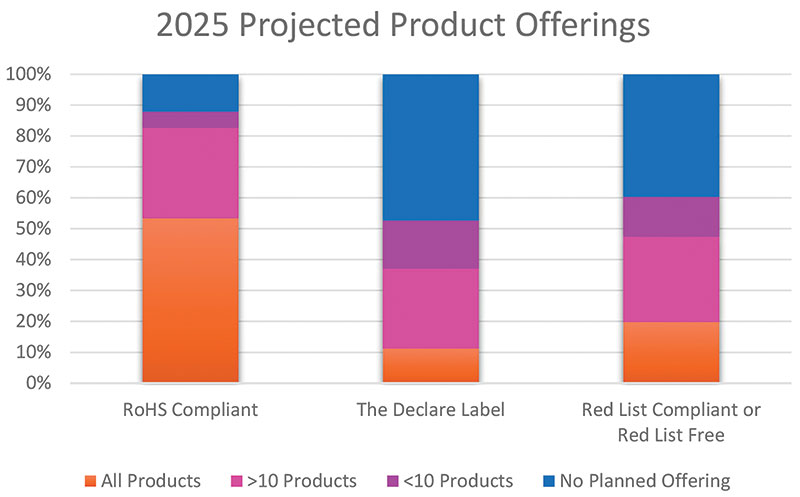

RoHS is a directive originating in the EU restricting the use of 10 hazardous materials found in electrical/electronic products. Although this was a well-known directive, we found only 30% of manufacturers list this compliance data on their specification sheets and less than 10% offer the ability to search by RoHS-compliant product on company websites, making it difficult for specifiers to give preference to these products. However, after taking the survey, 40% of manufacturers said they would consider adding RoHS compliance data to their specification sheets, and 47% said they would consider adding this search criteria to website product finders. Even more impressive, 53% of manufacturers reported plans to offer a line card with 100% RoHS-compliant luminaires by 2025, a clear indication of increased care around sustainable manufacturing choices, human health and well-being in the U.S.

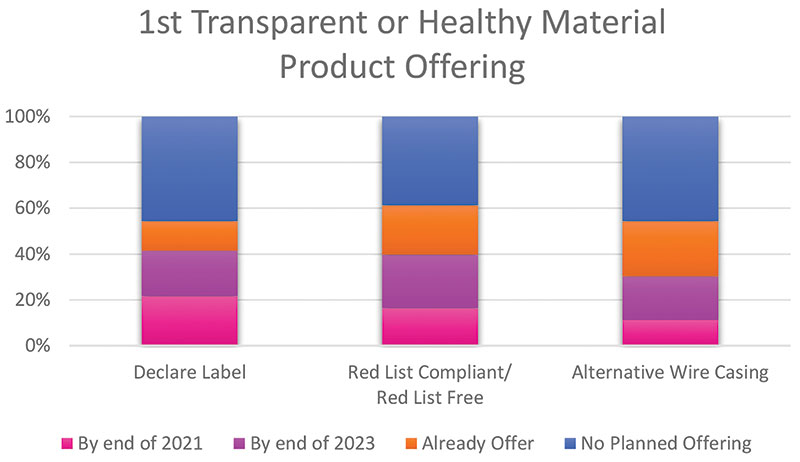

The Declare Label was the second human health focus area of the survey, which is a product label providing material disclosure in a simple and easy-to-use format, quickly identifying hazardous ingredients. Some 15% of manufacturers reported currently working on a Declare Label. Looking forward, 40% of lighting companies have plans to offer their first Declare Labeled product by 2023, a very promising trend (Figure 3). Five-year projections showed that half of manufacturers plan to provide material transparency through the Declare Label by 2025 (Figure 4). Even with a cost exceedingly higher than its Health Product Declaration (HPD) counterpart, this label seemingly continues to gain popularity as a preferable platform due to its easily digestible format and elegant presentation.

The last human health section of the survey questioned manufacturers regarding the Red List. This list of 22 chemical families is largely comprised of bio-accumulative toxins that are the worst-in-class materials and chemicals ubiquitous in the built environment. The 22 families translate to over 800 individual chemical CAS Registry numbers, such as lead, PVC, flame retardants and polycarbonates, which are often found in luminaires. A common use of PVC and flame retardants is in wire jacketing. While 30% of manufacturers were able to provide alternative wire casing upon special request, only 11% offer this as a standard. Nineteen percent of manufacturers reported plans to offer alternative wire casing by 2023 (Figure 3), and 32% reported they would consider doing this after taking our survey.

The Declare Label offers three label designations: “Declared,” which simply discloses all ingredients, “LBC Red List Approved,” which indicates a Red List chemical but relies on an exception for compliance, and lastly “LBC Red List Free,” which indicates zero red list chemicals present in the product. While 16% of lighting companies reported plans to offer their first Red List Compliant or Red List Free luminaire by the end of 2021, 23% plan to offer their first within two years’ time (Figure 3). Even more astounding, 20% of manufacturers stated they expect to offer their entire line card as Red List Compliant or Red List Free by 2025 (Figure 4), our strongest trend indicator yet.

Climate Impact: The climate impact portion of the survey focused on EPDs (Environmental Product Declarations). With only 8% of manufacturers offering this level of insight to climate impact, this label has yet to become popularized in the lighting industry. But that does not negate its importance. The foundation of any EPD is a Life Cycle Assessment (LCA), which considers the full value chain from extraction through manufactured product, its usage stage and end of life. However, because the usage stage is the most environmentally impactful portion in a luminaire’s life cycle, it’s critical we have a Product Category Rule (PCR), which dictates how to complete the LCA that is designed to evaluate luminaires specifically. Until now, lighting manufacturers have had to use more general PCRs that are poorly adapted for luminaires, leaving big gaps in the data sets. However, for the first time a new PCR for luminaires is set to be released this fall. To evaluate the true global warming potential of a luminaire through the lens of an EPD, it will be critical for manufacturers to adopt the new luminaire-specific PCR as the basis for their EPDs. LCA data is even making its way into BIM models, so looking forward, it’s likely EPDs will become the most comprehensive method to evaluate a luminaire’s global warming impact.

Ethical and Social Justice: The survey also aimed to evaluate the ethical and social justice operations of lighting companies by reviewing their sustainable corporate commitments, their commitments to employee well-being and their engagement with The JUST Label or Certified B Corporation commitments. The overwhelming majority had not explored a transparency label disclosing their operations relating to social justice issues, however 65% expressed interest in learning more about available certifications.

In February 2021, SFIL shared the results of our research through our local IES Section in a virtual event. This event became a launching point for a series of new conversations on the topic of sustainable lighting and material transparency and is at the forefront of trends evolving in the lighting industry. The more designers and specifiers ask manufacturers for material transparency with their products, the more momentum the movement gains.

One of the most powerful conversation starters begins by connecting with people’s values. More often than not, the only sustainability goal for a project is the pursuit of LEED or WELL. When we take a step back and understand the why behind ownership’s decision to pursue building certification, we gain insight into their deeper philosophy or policy that has motivated their sustainability goals. By opening the conversation in this way, the focus shifts from what is required to what is possible. For example, is there a particular core value connection to occupant well-being regarding material toxicity, attention to supply chain management to minimize impacts on natural air and water systems, focus on the overall carbon footprint of the project, concern for the ethical operations of suppliers with attention to human rights and worker well-being, or interest in design for disassembly and reuse? These holistic focuses are bucketed into human, ecosystem, climate and social health in relation to a circular economy. Using these holistic concentrations from the AIA materials pledge is a straightforward way to lead the conversation.

Even when sustainability is a small project goal, we can include these topics in the conversation. At your next project kick-off, aspire to obtain group buy-in on one of the five overarching holistic categories as a commitment for the project.

For example, can we specify all light fixtures to comply with the RoHS directive? Can we include two or three large quantity fixture types to have an HPD or Declare Label? Many manufacturers indicated in our survey that they would be willing to provide material transparency labels with a potential order. These conversations support the manufacturers by providing more market opportunity for those who are giving attention to holistic sustainable goals.

When a project has a larger focus on sustainability goals, the conversation evolves to higher bars, such as net-zero carbon, by focusing on both operational and embodied carbon impacts. When ownership has this inherent focus, our civic responsibility to meet these goals becomes an easier part of the conversation, including the part each party will play in achieving them. In this case, until there are more transparent products on the market available for specification, we suggest targeting the top one to three main fixtures, by quantity, to have a Declare Label that is Red List Approved or Red List Free. In this way, we are taking one step above transparency and asking for only safe materials in the most abundant fixture. As more products become available for specification, we can continue to aim for loftier goals, hopefully even in just six to 12 months from now.

While you are waiting for your next project kickoff to begin these conversations, try getting your feet wet at your next product tabletop presentation. Ask the manufacturer or your lighting rep:

- What is your stance on material health?

- Do you offer any products with material transparency labels such as Declare, HPDs, EPDs, etc.?

- Do you offer PVC-free wire casing for your products as a standard offering or possible modification?

- Do you offer any take-back programs for your products or information on end-of-life suggestions for the product?

- Is the product easily serviceable for replacement parts on-site? (For example, LED boards and drivers.)

- If not today, do you have any planned future offerings for products with these criteria?v

The answers to these questions could go a long way to ensuring material transparency in the not-too-distant future.