In the April edition of LD+A, contributor Don Peifer argues that the most-used metric in lighting industry—the lumen is hopelessly flawed. An excerpt follows here:

It’s possible today to design a lighting product that from one perspective is the perfect tool for an application yet from another is a complete dud: dead on arrival. At the heart of the issue are the metrics we use to describe performance and quality of light in our industry. These metrics are esoteric, poorly understood and fail to successfully encapsulate the essence of a successful lighting product. In fact, in certain cases, they can be downright misleading.

Take, as an example, luminous flux and its unit the lumen. It’s easily the most used metric in our industry, yet most lighting professionals would be hard-pressed to explain what it is. Lay people, who have grown accustomed to basic incandescent wattage equivalence to infer magnitude of light, are now faced with lumens on all the packaging of consumer brand lighting products and find it as incomprehensible as we pros.

So, what is it? Technically, luminous flux is the time rate of flow of light, which is a tough concept to wrap your head around. Its electrical counterpart is current, the unit of which is the Amp; again, which is not much help. We could play the devil’s advocate and say we don’t need to understand it. In a very general sense, a fixture receives watts and emits lumens. Its ability to effectively do that&mbash;its efficacy measured in lumens per watt—describes how successful it is, right? No, not necessarily.

TASK EFFICACY

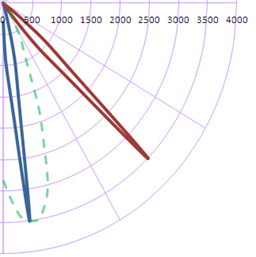

Let’s use a popular application, the grazer, as an example. For this application you want to evenly illuminate the surface being grazed, while pulling out the textures of that surface. Ideally you would want a long, narrow beam to run almost parallel to the surface you are grazing. Fluorescent grazers use scoop-like reflector optics to shape a wide distribution into a fairly narrow beam. A typical 4-ft T5HO (dotted green line in Figure 1) might achieve peak intensity of 3,500 candela using 54 watts of energy.

The promise of LEDs is that we can put light where we want it and keep it off where we don’t. Working with the wider fluorescent beam as a template, we can create a much narrower beam (blue line in Figure 1) and hit the same intensity values. A narrow beam instead of a wider beam allows us to save energy. In addition, the narrow beam will create a harder shadow, the likes of which you want in grazing application because it throws textures on the grazing surface (like a brick wall) into relief. This increases contrast and creates a point of interest in the space.

And, where the fluorescent used 54 watts, LED might be able to achieve the same intensity using only 17 watts of power. Seems like the perfect grazer. Because of the zones the intensity occupies, however, this beam only generates 300 lumens. That provides a system efficacy of only 17 lumens per watt, which is really the kiss of death in today’s efficacy-conscious world.

Here’s where it gets strange. If you take that same grazer curve and simply shift the peak from 5 to 45 deg (red curve,) your lumen values jump from 300 to over 1,700. You’re efficacy is now 100 lumens per watt by benefit of simply tilting the light up slightly, and your fixture transforms magically from goat to hero. The amount of lumens is relative to how the intensity is distributed, and, as such, it is an arbitrary, flawed metric. A much more helpful metric, candela per watt, which we could call grazing efficiency, would communicate much more about how a fixture preforms in an application rather than lumens per watt.

TROFFER EXAMPLE

Let’s use the ubiquitous recessed troffer as another example of how lumens fail us. The predominant metric used to communicate performance with this product type is system efficacy. One hundred lumens per watt is an increasingly typical performance target, so how do we achieve it? One way is to increase the number of LEDs and drive them at a lower current—extending life in the process. Another, more likely scenario given demands for quick payback by clients is to use a lighter-textured, higher-transmission optic instead of adding LEDs. Never mind that you’ll be able to see the pixilation of LEDs through the lens. Never mind that your distribution will get narrower and the uniformity in the space will suffer greatly. Your lumens per watt will be higher, you’ll qualify for rebates and you won’t dramatically increase your cost of goods. Priorities, more than ever, are biased for the tactical, short-term goals such as cost over long-term concerns such as quality. In this application, uniformity would tell us much more about the quality of luminaires, but we are stuck with lumens. Thanks more than ever to the role of regulatory agencies tying rebates to lumen-based metrics, we appear to be stuck with the devil we don’t know.

That’s a shame because the metrics we choose to champion play a large role in creating our future quality of light story. As we populate the built environment with products designed to last decades, what kind of a quality scene are we setting: good enough? Maybe, not even. We may bemoan the poorly lit fluorescent environments of our youth, but what criteria are we following today in schools, for example, that will make it any different for the next generation? The problem is that we don’t know what we don’t know. We’re fettered as an industry with paralyzing arcane metrics. The color metrics we are currently ushering in would seem to require an advanced degree to fully comprehend. It shouldn’t be this hard. The application tells us what it needs. We just need to listen and find good ways of communicating that. Easier said than done, no doubt, but it’s a step in the right direction away from the great unknown and back toward quality. For now, maybe we can all agree: there’s more than one way to judge a fixture.

April 2016