By A.P. Sachintha De Vas Gunawardena.

LED technology is now preferred over conventional light sources due to its better energy efficiency, customizability and superior performance. One of the claimed benefits of LED lighting systems is long useful lifetime. Today, LED lighting systems are used in many applications and experience a wide range of thermal and operating conditions. Although the life of the LED package is expected to be very long, the system life may be shortened due to the failure of the LED driver, a critical electronic component required for operation. Understanding the factors that contribute to the failure of LED drivers is vital to estimating the useful life of an LED lighting system and designing more reliable drivers suitable for their operating conditions.

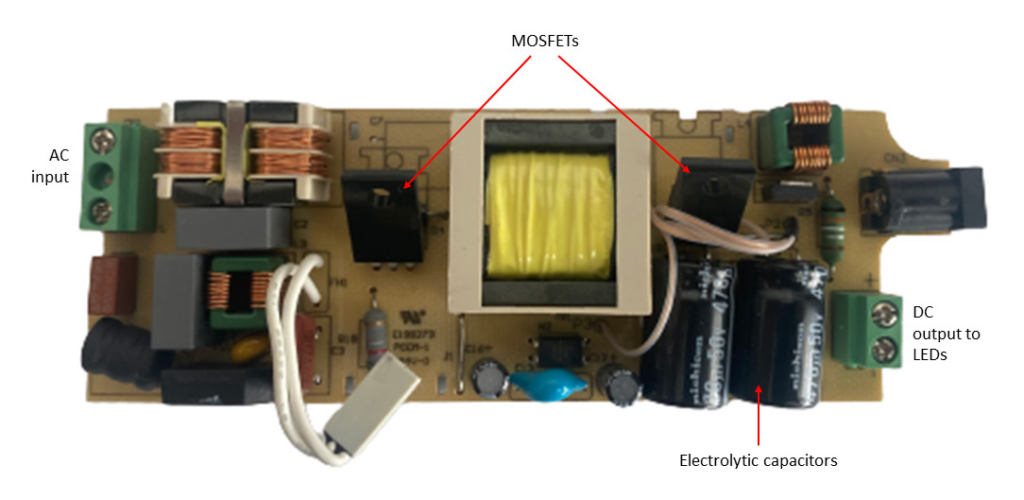

LED drivers operate similarly to constant current, switched-mode power supplies (SMPS). A commonly accepted test method for estimating LED driver lifetime does not exist. Currently, the industry uses statistical methods based on data from reliability handbooks (such as Telcordia SR-332, and MIL-HDBK-217) to estimate the lifetime of LED drivers. However, these methods generally fail to account for real-world use patterns, the operating environment conditions found with lighting systems, and how the parametric (i.e., gradual) degradation of the driver’s components interactively affects its failure. Therefore, as part of my doctoral research at Rensselaer’s Lighting Research Center (LRC), the LRC’s staff and I have sought to develop a lifetime estimation method for LED drivers by testing the most-often failed components under real-life operating environments and use patterns. Because past studies have revealed electrolytic capacitors and semiconductor switches at the DC-DC conversion stage of SMPS to be the two components with the highest failure rates in an LED driver, our study analyzed the parametric degradation of these two components.

Capacitor testing. Capacitors are used as primary or secondary voltage ripple filtering elements in switched-mode LED drivers to smoothen the output. Aluminum electrolytic capacitors (AEC) have a higher capacitance-to-volume ratio than other capacitor types such as film and ceramic, and hence are commonly used in compact applications such as LED drivers. They are also relatively cheaper than other types of capacitors. However, one drawback of electrolytic capacitors is their reliability issues over time that may lead to the shorter overall life of systems that use such capacitors. The state of health of AECs depends on factors such as operating temperature, voltage, current ripple and charge-discharge cycles, all of which lead to internal heat build-up and evaporation of the electrolyte inside. Electrolyte evaporation results in drift in mainly two parameters of the capacitor: reduction in capacitance and increment in equivalent series resistance (ESR).

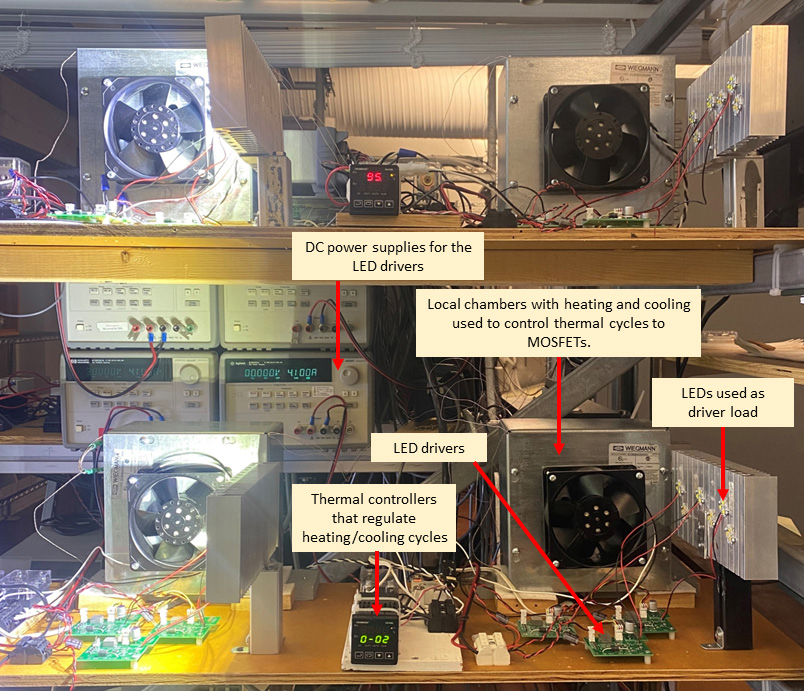

Past studies have investigated the parametric degradation of electrolytic capacitors under constant thermal stresses, but not under cycled thermal conditions, which are commonly found with lighting systems. For example, a lighting fixture may be operated for 6 hours per day in a residential application with multiple switching On/Off cycles, whereas in a commercial application, the fixtures may be operated continuously for 12 to 24 hours per day. Therefore, in this study, peak temperature and thermal cycles with different on-times were selected as acceleration factors to study the effects of power/thermal cycling on the life of electrolytic capacitors in LED drivers. The experiment measured the driver’s peak-to-peak output voltage changes under the output stage capacitor’s continuous and power/thermal cycled conditions. A commercially available LED driver was used in the experiment. The electrolytic capacitor at the output was removed from the driver board and isolated in a local oven while electrically connected to the circuit.

The accelerated life test showed that the LED driver’s useful life had an inverse exponential relationship to the operating temperature of the output capacitor. The thermally cycled conditions did not indicate the introduction of additional failure mechanisms in electrolytic capacitors; electrolyte evaporation was still the prominent failure mechanism within the tested temperature range. A mathematical model based on experimental results was developed to estimate the time-to–failure of LED drivers as a result of the capacitor’s parametric degradation by considering the exponential shortening of life with temperature and operating thermal profile.

Semiconductor switch (MOSFET) testing. As mentioned earlier, the semiconductor switch is another frequently failed component in LED drivers. Therefore, in a separate study, the impact of the degradation of semiconductor switches in the DC-DC conversion stage of LED drivers was investigated. MOSFETs in LED drivers are used as voltage-controlled switching devices due to their operating power level, high switching speeds and low on-state resistance. MOSFET failure mechanisms can be divided into chip-related and package-related categories. In LED driver applications, voltage and other electrical overstresses are minimal on MOSFETs. Hence, the applicability of chip-related failure mechanisms is assumed to be low. However, power cycling of the drivers and resulting temperature swings will activate package-related failure mechanisms. Therefore, in this study, package-related failure mechanisms are considered for the life test of MOSFETs. Past literature suggests different parameter changes with the degradation of MOSFETs. Out of those, the on-state resistance (Ron) increase is associated mainly with packagerelated failure mechanisms.

Degrading a MOSFET in the DC-DC conversion stage of a switched-mode LED driver can impact the driver’s efficiency due to increased conduction losses in the switching element. Also, it can increase the probability of the MOSFET’s catastrophic failure due to the rise of power dissipation in the on-state resistive element. Therefore, the on-state resistance increase was used as a failure precursor of the MOSFETs in the experiment, which was measured by offline I-V characterization.

The experiment was conducted to evaluate the effect of temperature cycling and temperature-induced creep stress on the degradation of MOSFETs. A constant-current DC-DC LED driver was designed for the experiment, and multiple samples were developed in-house for testing under the experimental conditions. Three maximum MOSFET case temperatures and three different power/thermal cycling profiles (with dwell times ranging from one to three hours) were selected as accelerated aging conditions for the MOSFETs. The case temperatures were within the operating limits of the MOSFETs.

The results suggested that the number of thermal cycles and higher operating case temperatures accelerate the increase of on-state resistance, suggesting both factors contribute to package-related degradation with time. A mathematical model based on experimental results was developed to quantify MOSFET parametric degradation as a function of operating temperature and power cycling profile. This model will help determine the parametric degradation of MOSFETs in practical operating conditions and can be used to determine an LED driver’s performance (in terms of conversion efficiency) with time.

Future development. As a final step of the study, we expect to develop a method for estimating the life of an LED driver by considering the individual and mutual effects of the component degradation of electrolytic capacitors and MOSFETs. A simulation-based technique will be employed in this step, which can be further developed into an experimental method. Once this study is complete, we hope the findings will influence a greater understanding of the failure modes and failure mechanisms of components in an LED driver under real-world operating conditions. The findings may also guide LED driver manufacturers, fixture integrators, and lighting professionals in evaluating the long-term performance and useful life of an LED lighting system, as well as guide industry regulators on what conditions should be analyzed when developing a standard test method for LED driver useful lifetime.

THE AUTHOR

A.P. Sachintha G. De Vas Gunawardena is a doctoral candidate at the Lighting Research Center at Rensselaer Polytechnic Institute studying solid-state driverlife and driver component reliability. His research interests also include additive manufacturing of SSL luminaires and functional 3D-printed electronics.