The need to standardize sensors

By Kate Hickcox and Michael Myer

Although many luminaires in buildings are being replaced or upgraded with LED technology, few of the LED luminaires and retrofit kits sold today are equipped with connected lighting systems or Internet of Things (IoT) capabilities. To date, only approximately 1% of installed lighting systems are equipped to leverage connectivity between lighting devices and with other building systems for the purpose of realizing additional savings and value.1 This technology lag represents a major lost opportunity both today and in the future.

Connected or IoT-enabled luminaires supply data from sensors, which can increase energy savings, support sustainability goals, and improve building and business systems or operations via asset tracking, space utilization, wayfinding, CO2 sensing, contact tracing or many other applications.

Why focus on luminaires as the connection hub for these advanced sensors or IoT applications? Lighting already serves as an “eye in the sky” in many spaces and offers a good line of sight for sensor applications. Luminaires have both power and the physical space to hold a sensor and control gear. Some luminaires already use sensor technology (e.g., occupancy sensors for energy and space utilization) like that required by IoT applications. These factors make luminaires excellent receptacles for smart sensors and controls.

Illustration: PNNL

GIVEN SUCH CAPABILITIES, WHY AREN’T WE SEEING more widespread use of advanced sensors? One reason is the lack of standardization of lighting sensor ports and communication. As a result, interoperability, interchangeability and upgradeability become problematic.

For example, if building owners or facilities managers install IoT-enabled luminaires today, they may be locked into single-vendor proprietary solutions should they want to upgrade or expand the lighting system in the future. Lack of standardization can also affect engineers and designers by limiting competition and making construction administration more difficult as it limits open specification. Specifiers want future-ready luminaires that support open specifications and bidding. Such capabilities provide multiple options of controls and IoT vendors separate from the luminaire specification.

To allow for widespread adoption and successful long-term installations of connected or IoT luminaire systems, the industry needs standardization around data exchange, and a standard physical sensor interface to allow for future-proof flexibility of sensor selection.

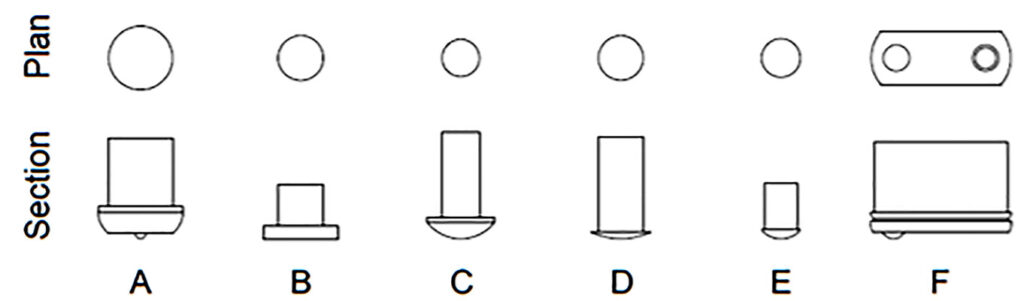

Currently, there are many sensor dimensions and connection types on the market. These can vary widely in both connection aperture shape and keep-out space. Keep-out space, the volume inside and outside the luminaire where the sensor and its components will be mounted, must be kept open and free from other components or elements. Luminaire manufacturers may need special tooling for each lighting control manufacturer’s sensor due to the wide variety of existing dimensions. For a luminaire manufacturer that wants to be sensor agnostic, such tooling can quickly become a logistical issue. Figure 1 depicts a small sample of dimensions for round sensors currently available. There are many other shapes of sensors and the overall sensor market currently has many different form factors and dimensions.

Illustration: PNNL

FOR MANUFACTURERS OF LUMINAIRE-LEVEL LIGHTING CONTROLS (LLLC), the shape and size of lighting controls, the keep-out space and the electrical/data connection for the sensors all present a concern. The current lack of standardization in the market limits the use of LLLCs by limiting sensor options or requiring extensive coordination during construction administration. During the design phase, the sensor must be paired with the luminaire. However, if a different vendor is required, the design team must make sure that the luminaire can accommodate the new sensor connection aperture, mounting type and dimensions (the sensor must fit within the open keep-out space in the luminaire). A common set of connection apertures and keep-out spaces would reduce this risk and burden on the design team.

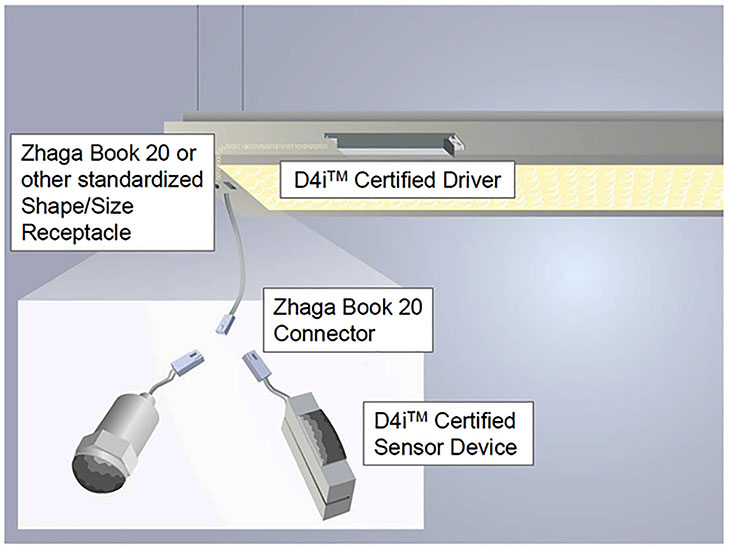

Illustration: modified by PNNL with approval from Zhaga

Two other efforts began in 2020. The National Electrical Manufacturers Association (NEMA) began a similar effort related to sensor dimensions. NEMA’s draft document (in early stages as of this publication) specifically includes the Zhaga keep-out space configurations and connection apertures as well as other keep-out space options.

Pacific Northwest National Laboratory (PNNL) has been developing an IoT-Upgradeable Lighting Challenge that would take advantage of some of these specifications to help promote adoption of advanced sensors and IoT applications. As part of the development of this upcoming challenge, PNNL conducted an analysis of existing luminaire-mounted (internal or external) sensors from more than 20 North American sensor manufacturers. The analysis assessed whether the existing sensors on the U.S. market would work with the new Zhaga Book 20 specifications and with the draft NEMA document. The resulting survey focused on sensors in the U.S. market with an electrical or data interface of either low voltage or DALI; the survey excluded any sensors that were line voltage. PNNL compared the internal keep-out spaces and mounting apertures of the 61 sensors on the survey list with the published Zhaga Interface Book 20 specifications and the NEMA draft specifications. In this survey, it was found that an additional sensor type, an externally mounted sensor often seen in low- or high-bay installations, was also very common in the U.S.

Illustration: PNNL

PNNL found that many of the existing sensors on the North American market already meet the sensor shapes defined by this Zhaga standard, even though the standard has a limited number of sensor shape options (2 rectangular, 1 cylindrical, 1 rectangular with cylindrical sensor). Of the 61 sensors that PNNL reviewed, 62% would work with both the Zhaga Interface Book 20 internal keep-out specification and components of the NEMA draft specification (Figure 2). Other sensors were close and could meet the defined specifications with small modifications.

Standardizing mounting apertures, keep-out spaces and the electrical/data connection will make it possible to upgrade the luminaires of the future, and could lead to simpler lighting controls installations. Such standardization focused on the physical connection between the sensor and driver, as well as the shared data and protocol, would make a variety of sensors “plug and play” in many different luminaires—in both initial installation and retrofits. Luminaire manufacturers could then develop future-ready luminaires that can be installed or upgraded (before or after installation) with a wide variety of sensors across multiple manufacturers.

Reference